Among these, injection molding and the associated procedures such as undercut injection molding and reaction injection molding have become essential for manufacturing plastic components. Plastic injection molding manufacturers make use of innovative equipment to infuse liquified plastic right into mold and mildews, creating parts with complex styles and tight tolerances.

The principle of undercuts in injection molding entails features that avoid the component from being ejected straight out from the mold, demanding additional intricacy in mold style. Undercut injection molding uses retractable cores or side actions, permitting for the successful molding of attributes such as internal threading or side openings.

Supplementing conventional molding procedures, rotational molding provides an additional avenue for producing hollow parts. Rotational molding machines warm vinyl or plastisol in a mold that gradually rotates, guaranteeing even worldly distribution to create a consistent wall surface density. Rotomolding is especially valuable for creating huge, hollow objects such as storage tanks or kayaks. Additionally, techniques like vacuum casting provide an adaptable alternative for creating plastic and rubber parts, specifically helpful throughout prototype growth or low-volume production runs. Urethane casting, carefully associated, makes it possible for the creation of high-grade parts by pouring polyurethane into silicone molds under vacuum.

Within the realm of 3D printing, DMLS (Direct Metal Laser Sintering) and SLS (Selective Laser Sintering) have transformed exactly how complicated metal and plastic parts are produced. DMLS 3D printing concentrates on metal components, utilizing a laser to sinter powdered metals right into strong, high-resolution parts. This process is excellent for producing complex geometries and components with tight tolerances. Similarly, SLS 3D printing involves a laser sintering powdered materials, usually thermoplastics, into durable parts without the need for support frameworks. The flexibility of these technologies accelerates the design-to-production timeline, enabling quick prototyping and on-demand manufacturing of parts that would commonly call for complicated tooling.

Horizontal milling machines are fit for working on parts with numerous sides or for removing big quantities of material swiftly. In procedures like slot milling and slot machining, specialized slot milling devices assist in developing slots and grooves in parts with accuracy and precision. Tight tolerance machining is important for ensuring components satisfy rigorous specifications, particularly in aerospace and clinical applications where precision is extremely important.

Additionally, modern-day CAM (Computer-Aided Manufacturing) software incorporates seamlessly with CNC (Computer Numerical Control) machinery, making it possible for complex machining tasks to be carried out with high accuracy. CAM software not just aids in machining and milling procedures but likewise addresses difficulties associated to machining tolerance, making certain parts are fabricated within certain dimensional requirements regularly. The combination of CAM milling with CNC systems has reinvented manufacturing lines, considerably improving both speed and high quality.

Casting metals, such as aluminum and steel, continues to be a relied on method for creating parts with high dimensional security. Investment casting, additionally called lost-wax casting, is an adored process for producing parts with intricate designs and outstanding surface area coatings. This technique involves creating a wax pattern, covering it in ceramic material, and ultimately thawing the wax to leave a mold tooth cavity. Molten metal is then poured right into this dental caries to develop the preferred part. Aluminum investment casting, specifically, is commemorated for creating lightweight components with high strength-to-weight ratios, as made use of in aerospace and vehicle applications.

When casting is not suitable, sheet metal fabrication techniques come right into play, including a variety of procedures from punching, forming to welding. Punching procedures in sheet metal, supported by innovative punching machinery, can create openings and intricate layouts with specific force application. Similarly, sheet metal forming includes flexing and forming operations to attain the preferred geometries. Prototype sheet metal fabrication enables for the testing and refinement of layouts before devoting to large-scale production.

The flexible household of materials known as composites also locates applications within these innovative manufacturing techniques. Carbon fiber compounds, renowned for their high strength-to-weight proportion, enable the construction of read more light-weight yet robust components utilized extensively in automotive parts and sporting activities tools.

In the world of welding, different techniques accommodate certain material types and thicknesses. Sorts of welding, consisting of MIG (Metal Inert Gas) welding, TIG (Tungsten Inert Gas) welding, and place welding, are picked based on their heat generation and infiltration features. Welding techniques have actually progressed, enhancing the strength and honesty of joints in sheet metal and structural applications, increasing their applicability in manufacturing situations.

Coming with the abovementioned processes are considerations for defects and top quality assurance. In rubber compression molding, defects such as air pockets or incomplete loads are carefully monitored and resolved with process optimization. Rubber compression molding techniques involve pressing a pre-heated rubber compound in a warmed mold under pressure. This process is specifically helpful for producing durable seals and gaskets widespread in automobile and mechanical systems.

The concept of undercuts in injection molding includes functions that stop the component from being ejected right out from the mold, necessitating additional intricacy in mold layout. Undercut injection molding uses collapsible cores Sheet Metal Punching or side activities, permitting for the successful molding of features such as interior threading or side holes. On the other hand, reaction injection molding includes a combination of two fluid components, generally an isocyanate and a polyol, which increase and respond within the mold tooth cavity. This method is especially useful for producing lightweight, durable get rid of intricate geometries and is frequently used in the vehicle sector for manufacturing bumpers and other large components.

Supplementing conventional molding processes, rotational molding supplies an additional opportunity for developing hollow parts. Rotational molding machines warm vinyl or plastisol in a mold that gradually turns, making sure even material circulation to develop a consistent wall surface thickness.

The evolution of products and manufacturing innovation reshapes exactly how sectors run, creating a dynamic interaction between traditional and sophisticated procedures. With developments like direct metal laser sintering and precision-oriented CAM milling paired with the tried-and-true approaches of casting and forming metals, manufacturers are armed with a collection of options to fulfill Urethane Casting modern-day manufacturing needs. Whether it's the rapid manufacturing capacity made it possible for by injection and reaction injection molding or the precision attainable with CNC machining and investment casting, comprehending the nuances and ideal applications of these processes makes certain that markets can react agilely to changing needs while keeping quality and performance. Each technology matches the various other, forming a cohesive framework sustaining the production of whatever from day-to-day products to critical engineering components.

Judge Reinhold Then & Now!

Judge Reinhold Then & Now! Burke Ramsey Then & Now!

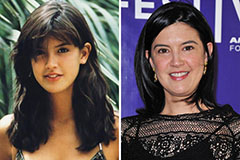

Burke Ramsey Then & Now! Phoebe Cates Then & Now!

Phoebe Cates Then & Now! Tyra Banks Then & Now!

Tyra Banks Then & Now! Meadow Walker Then & Now!

Meadow Walker Then & Now!